Before humans and allegedly any animal group, spiders developed “functionally graded toothed blades” that cut one of the toughest biological materials: silk.

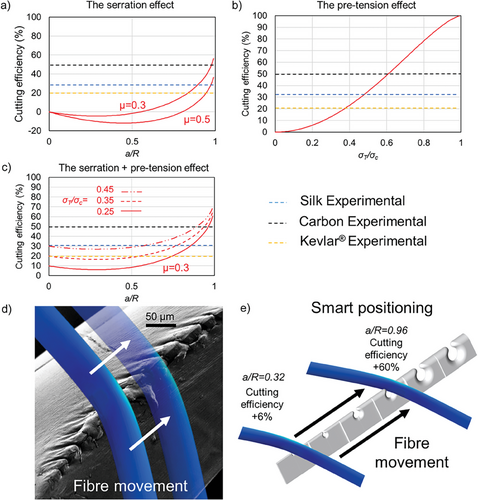

Here, this work reveals the importance of micro-structured serrations in spiders’ fangs that allow these animals to cut silk and artificial high-performance fibers, such as carbon or Kevlar. The importance of serrations revolves around the stress concentration at the interface between the fang and the fibers, resulting in a cutting efficiency superior to that of a razor blade. This efficiency is increased by the presence of pretension in the fibers and is high also for fibers with different diameters like silk, because of the serration grading that allows a smart positioning of the fiber in the optimal cutting condition.

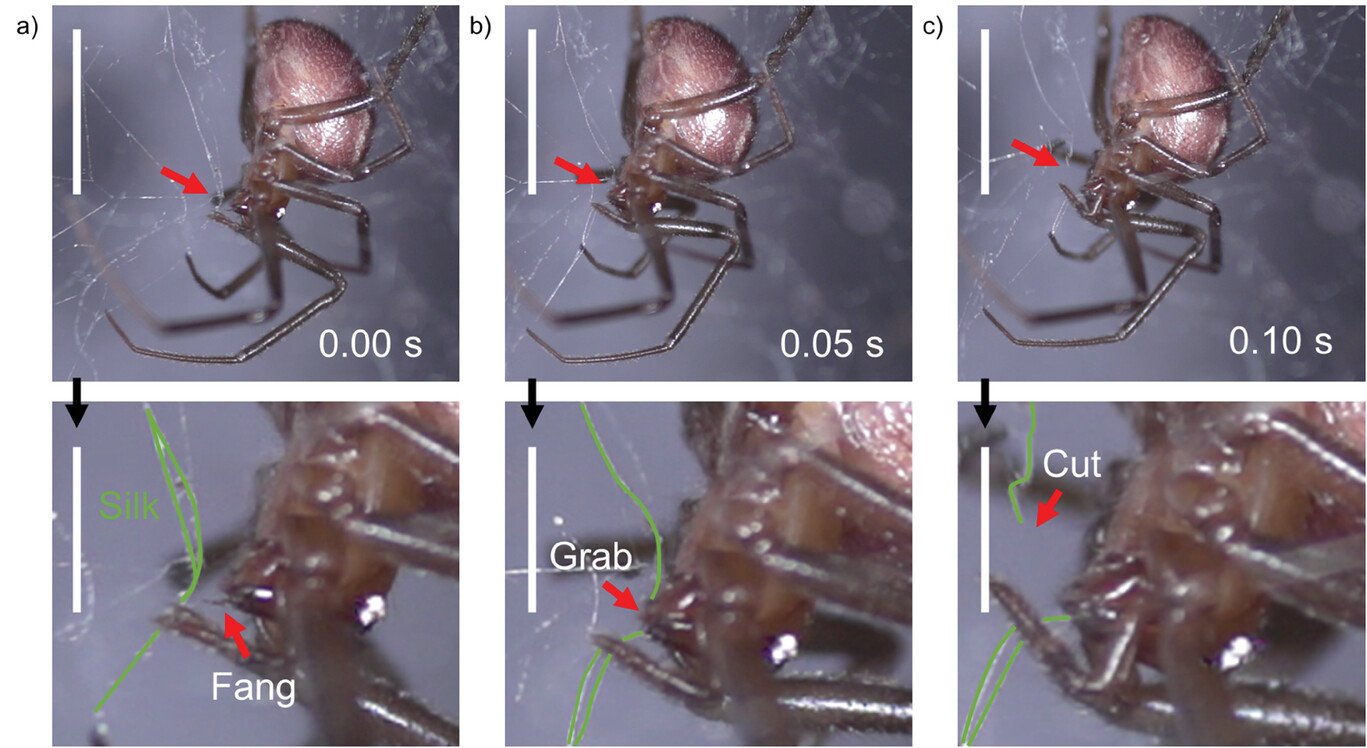

This work proposes that when the silk fiber is grasped by the fang, it slides along the serrated edge till it gets locked in the serration with a comparable size, where the load to cut is minimal. These results provide a new perspective on cutting mechanisms and set the roots for spider fang-inspired cutting tools.

By combining experimental, theoretical, numerical and biological approaches, we provide evidence that the cutting of silk lines is mechanically possible due to the presence of functionally graded fang serrations that could also allow fiber smart positioning before optimal cutting. Although this does not exclude the involvement of gastric enzymes in this phenomenon, it surely gives a solid reason for the pervasive distribution of fang serration among spiders. Here, we suggest that such a micro-structured serration has secondarily acquired a cutting function as a morphological tool to optimize cutting mechanics by reducing the forces necessary to break up silk fibers.

Very interesting!

In action:

The mechanics: